This guide is for an ae92. however the same principle for the ae101 non superstrut

This Guide will explain to you with pictures and detailed text, exactly how to install lowering springs on the AE92 GTi-16 Corollas.

This Guide also applies to the GL and Liftback Models.

You Will Need: *1/2" Drive Breaker Bar - A huge 800mm bar is necessary!

*Snub Nose Pliers *Screwdrivers - Old knackered ones you don't care about, although they do need to be sturdy!

*1/2" Drive Torque Wrench - Capable of 110Nm

*1/2" Drive Ratchet *1/2" Drive 19mm Hex-Head Socket

*1/2" Drive 19mm Long Reach Hex-Head Socket

*3/8" Drive Ratchet

*3.8" Drive 12mm Hex-Head Socket

*19mm Spanner

*WD40

*Latex Gloves

*Trolley Jack

*Axle Stands

*Coil Spring Compressor *Lump Hammer

Things You May Need: *Hacksaw

*LockTite Blue

*Thick Wooden Block

The list of things you may need is only for those who want peace of mind and who may have specifics types of suspension that require work. This list of things you need is the minimum list of tools needed to safely carry out the work mentioned in this guide.

Before you start you must take note of the following:

This How To: Guide is just that, a guide. It is not a set of official instructions, it comes with no guarantee of success or your safety. The AE92 Owners Club and myself (as KPARRIS-JONES, KP92, kpj-uk or any other "Forum" Name including my true name Kynan Parris-Jones) in no way accepts responsibility for any damage caused to yourself, your tools, your cars or persons etc. If you want to attempt this job then it is important that you perform your own personal risk assessment before you get stuck in. Plan your Job; take the time to understand the instructions and the implications of your own actions to yourself and others. If you get lazy and decide not to use a chain on the Coil Spring Compressor and the spring flies off and takes your hand with it - tough shit. Natural Selection would be rediscovered and you may even be able to claim PPI on a loan you carried out several thousand years ago! That's it for the legal stuff - enjoy your day of lowering!

1. Get your gloves on to keep your hands clean and away for all the nasties we find under our cars. Then slacken off all the wheel nuts.

2. When you have slackened the wheel nuts jack up the car from the central Sub-Frame that supports the engine. You may find that to get enough working room you need to jack up with a wooden block to take up some of the space - this allows the jack to reach higher. The picture below shows you what sort of height you need.

3. Remove the wheels and slacken the Strut-To-Hub Nuts using the 19mm Socket, 19mm Spanner and 1/2" Drive Ratchet. You will likely find that you need the 1/2" Breaker Bar as these are very tight and the threads get very dirty! You may find that you can slacken the bolt without using the 19mm Spanner, however you will need it when you get the bolt going and it hitches against the dirty thread ends.

4. Using the Snub-Nose Pliers, remove the Slider clip that holds the line to the damper. You will benefit from allowing it to soak in WD40 for a few minutes! You can also use the screwdriver to lever it away which is quite often the case. There are some cases where the bracket holding the brake line to the damper is in fact a fully closed bracket, meaning you will have to disconnect the brake line and bleed the brakes to remove the line and thus the damper. However you can take the easy way out and carefully saw around the line with a small hacksaw:

5. Fully remove the Strut-To-Hub nuts to free the damper from the hub. You will likely need to knock the bolts through to get them out. Use a Screwdriver and Hammer to knock them through forcefully.To access the nuts it may be necessary to use a 12mm socket to remove the calliper top slider bolt - this will allow you to slide the calliper out of the way.

6. Using the 12mm 3/8" Hex Head Socket, slacken and remove the Top-Mount nuts from the suspension strut. You will find these in the engine bay:

Watch out for when it drops, just be ready for a clunking noise. It is wise to support the damper with one hand so as to avoid damaging the final nuts thread from the stress.

7. Carefully remove the strut, avoiding brake lines and the bodywork!

It is sensible to replace your gloves regularly to keep your hands clean and to ensure that when a stray hand rests on bodywork, you don't get oil and grime on the paintwork! You will likely find you need to use a screwdriver to separate the strut and hub. The front suspension system utilises the McPherson type suspension system. This is what the AE92 McPherson strut looks like.

8. With the strut off the vehicle, rotate the Top Mount (the component with the 3 studs for the 12mm nuts) and check its bearings for wear, repacking them with CV Lith-Moly Grease upon reassembly.

9. Remove the centre cap using a flat-head screwdriver to reveal the Top Mount Securing Nut. With the 19mm Socket,

slacken the top mount securing nut - do

NOT remove it altogether unless you fancy a brand new nose.

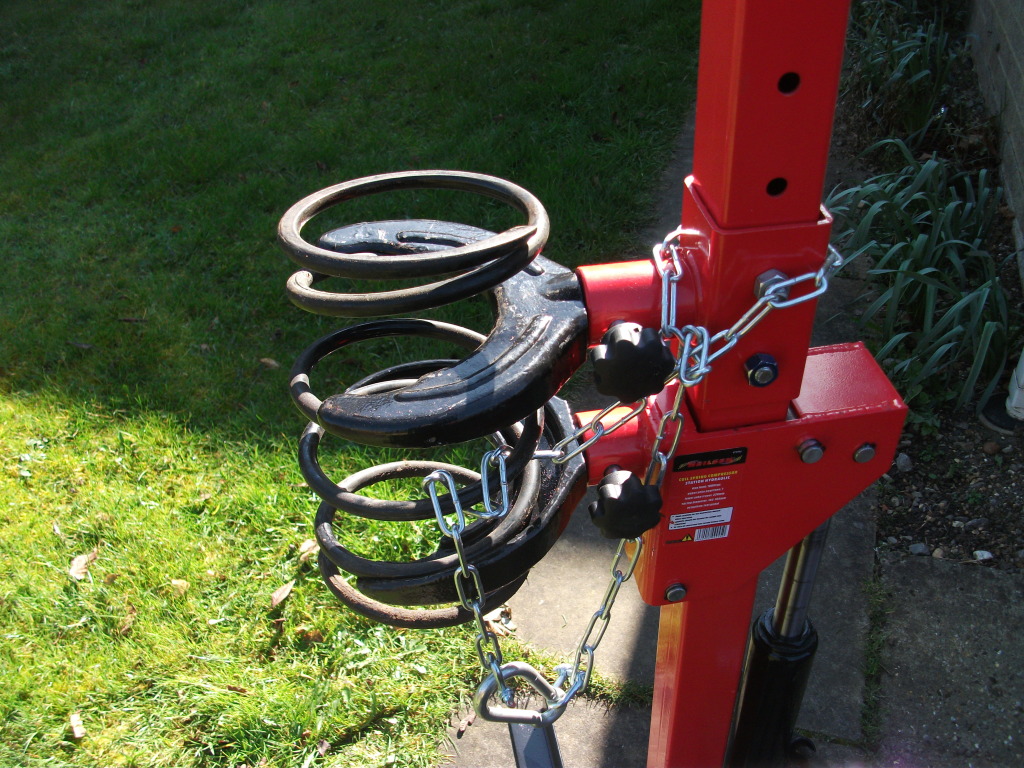

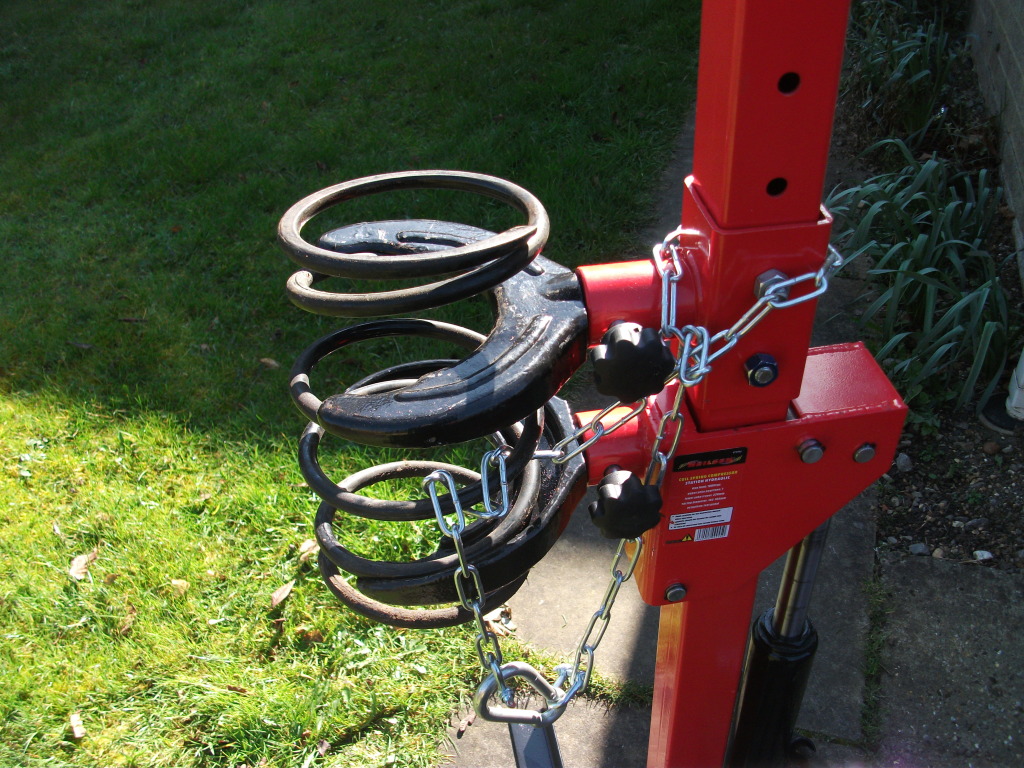

10. Place the strut into the Coil Spring Compressor, being sure that the spring is seated in the CSC seats correctly.

The previous pictures shows you where many people go wrong - the upper spring seat must face downwards to cup the spring correctly!

11. Secure the spring using a suitable chain and/or carabinar.

Failure to secure the spring correctly can result in serious injury or even necrosis if you're particularly unlucky - however do video the event if you're not going to use the chain as it'll be a good reminder to us all at home.

Failure to secure the spring correctly can result in serious injury or even necrosis if you're particularly unlucky - however do video the event if you're not going to use the chain as it'll be a good reminder to us all at home. 12. Pump the CSC to compress the spring until it lifts off both seats - maybe with some persuasion.

13. Remove the Top Mount securing nut altogether and remove the Top Mount Assembly. You will find there are 5 main components; securing nut, top mount studded plate, shim, upper spring seat and upper spring seat rubber cushion. Replace these components as necessary. The damper will simply drop to the floor when the nut is removed.

Take note of the way the whole McPherson Assembly goes together - you can fall foul to putting it together backwards which is a pain when you come to try and fit it again! Pictured below is the damper complete with bump stop, remember to refit it!

Top Mount Assembly

Relieve pressure on the spring slowly until you can remove it by hand.

14. Grab your new springs and just enjoy looking at them!

15. Place the new spring into the CSC, again making sure it is seated correctly.

16. Compress the spring until you can easily slide the damper back through from the bottom. But note the following: *Fit the Lower Spring Seat rubber cushion, taking note of where the spring end sits in the recess moulded into the seat and rubber. *Fit the Bump-Stop to the Damper

17. Reassemble the Top Mount Assembly, being careful to first put on the upper spring seat rubber cushion on, again in the correct place for the springs cut end. Then the upper spring seat sits on top of this rubber cushion. This must be oriented correctly to fit back onto the vehicle, read below for details: On top of the upper spring seat is an etched label "Out ^" which must face outwards from the vehicle - it must point in line with the forks of where the strut secures to the hub. Whilst making the adjustments to get it in the correct position, be sure that the spring hasn't moved out of the seat in the rubber cushion.

18. Screw on the top nut until the shaft spins inside the damper.

19. Slowly relieve pressure on the spring, ensuring it all sits correctly as it decompresses, so that you can then tighten the top nut properly.

20. Repeat for the other struts!

21. When you're ready to refit, ensure your vehicle is still secure on its axle stands - this can get rough and if you're as dim as me, you can find one stand slip from underneath the car....

22. Using considerable force and coarse language, slide the bottom of the strut over the hub again - get the bottom holes lined up well and then use the hammer to hit the bolt back through. Once you have this in you can relax more and add on the top bolt and nut.

23. Secure these bolts and nuts using the 19mm socket and spanner. You can use a torque setting however you will be fine to use the UESTS - Universal Engineering Standards Torque Setting, which is of course known as "Fucking Tight!"

24. Now push the strut up through the turret, aligning the studs so they push through. Get one nut on and start tightening it to drag the others up so you can bare some thread. This stage can be tricky if the lower arm refuses to allow you to push the strut up manually. If this is the case then follow these instructions:

a) Looking down from the turret, align the studs as well as you can.

B) Remove the axle stand on the offended side of the car and support the car on the jack.

c) Using a very steady hand, lower the car incredibly slowly so that the car starts to rest on the suspension. This is push the studs up to the holes on the turret. You must do this slowly so that you can make very fine adjustments to the stud positions to get them seated correctly.

d) When they are aligned properly, lower the car to rest on its own suspension and tighten up the top mount nuts with the 3/8" Drive 12mm Socket. e) Repeat for the other side.

This method can only work if you have the other end of the cars suspension assembled. 25. Get back on your back and secure the brake lines to the struts again. While you're down there, make sure you tightened the strut-to-hub bolts, just to be sure! 26. It should now look like this!

Put the wheels back on and hand tighten the nuts. 27. Carefully lower the car and remove the axle stands.

28. Go round every bolt you removed and check it for tightness again, these are integral components. You may be more comfortable using locktite blue on them to help them resist vibrations.

29. Take the car for a gentle test drive and ensure that everything is working properly. 30. Then hit the road hard and have fun!

If you have any further questions about this guide or lowering your AE92 then do not hesitate to contact me or any member of the AE101 Owners Club.

If you have any further questions about this guide or lowering your AE92 then do not hesitate to contact me or any member of the AE101 Owners Club.